LCA-13008-Replacement_Of_HE_Sensors_Procedure [lca-13008-replacement_of_he_sensors_procedure]#

Scope:

This document describes how to replace the Hall Effet Sensors listed below. Please read “initial configuration” and “staff required” sections that apply for each case.

1.1. Sensor_XP-LCA-13184-qty1 per AutoChanger 2

1.2. Sensor_XM-LCA-13166-qty1 per AutoChanger 3

1.3. Sensor_YM-LCA-13160-qty2 per AutoChanger 4

2.1. Truck_Sensor_Board_XM-LCA-13006-qty1 per AutoChanger 4

2.2. Truck_Sensor_Board_XP-LCA-13005-qty1 per AutoChanger 5

3.1. Truck_Position_Sensors_XM-LCA-12860-qty3 per AutoChanger 5

3.2. Truck_Position_Sensors_XP-LCA-12852-qty3 per AutoChanger 6

4.1. Limit_switch_position_sensor XP-LCA-13100-qty2 per AutoChanger 7

4.2. Limit_switch_position_sensor XM-LCA-13102-qty2 per AutoChanger 7

Initial configuration (for each case):

The autochanger is supposed to be empty (with no filter) on its Maintenance Bench #02-LCA-13140 in horizontal position (as shown on LCA-13140) in StandAlone configuration. It is connected to the electrical bay #04-LCA-13140. The three power supplies are turned off.

Staff required (for each case):

1 person with mechanical skills

1 person with electrical skills

1 person able to use the FCS

ONLINECLAMP SENSORS#

Sensor_XP-LCA-13184-qty1 per AutoChanger#

Scope:

This operation has to be considered if the position of the OnlineClamp X+ cannot be read on the FCS. Since every signal (OnlineClampX+ Open/OnlineClampX+ Closed) is doubled by a complementary one, the FCS is able to detect a sensor error.

The position of the Sensor_XP-LCA-13184 is given on #05-LCA-12946.

Material needed:

-

Small cross-point screwdriver qty 1

-

Small flat screwdriver qty 1

Procedure:

-

Make sure there is no filter in the AutoChanger and the power supplies are turned off.

-

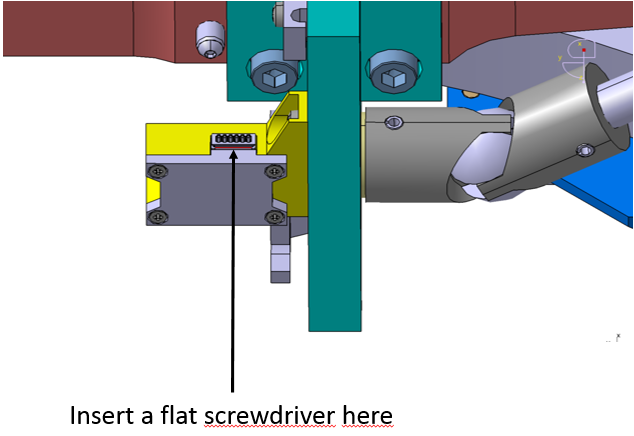

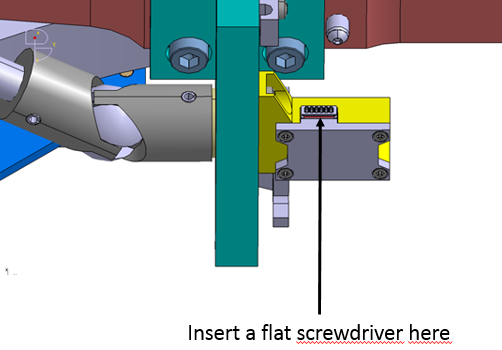

Remove the connector by levering between the socket and the connector with a flat screwdriver. Make sure not to pull on the cable. The correct position at which the flat screwdriver has to be inserted is shown in below:

-

Remove the screw #06-LCA-13184 with a small cross-point screwdriver.

-

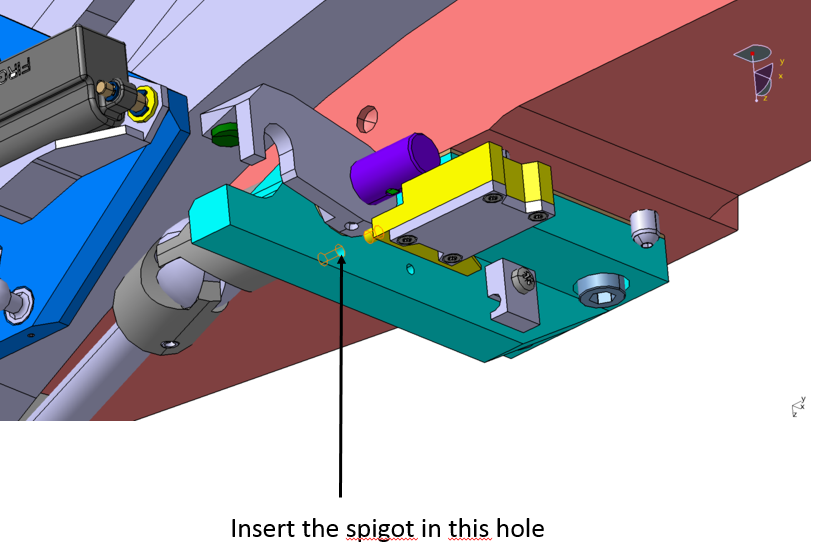

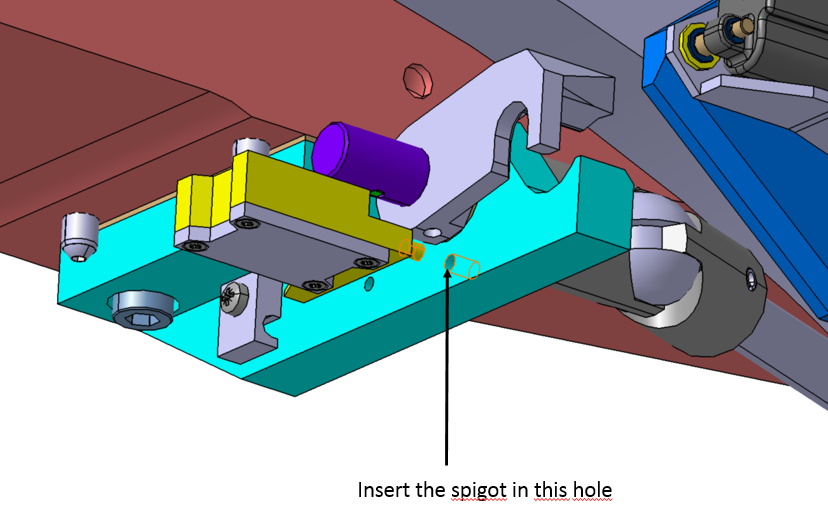

Pull the Sensor_XP and replace it by a new one. Make sure to fully insert the spigot of the Sensor_XP inside the clamp_XP #02-LCA-12946 as shown below:

-

Screw in the screw #06-LCA-13184 with a small cross-point screwdriver.

-

Plug the connector to the socket by pushing on the connector without bending the cables.

Sensor_XM-LCA-13166-qty1 per AutoChanger#

Scope:

This operation has to be considered if the position of the OnlineClamp X-cannot be read on the FCS. Since every signal (OnlineClampX-Open/OnlineClampX-Closed) is doubled by a complementary one, the FCS is able to detect a sensor error.

The position of the Sensor_XM-LCA-13166 is given by #05-LCA-12991.

Material needed:

-

Small cross-point screwdriver qty 1

-

Small flat screwdriver qty 1

Procedure:

-

Make sure there is no filter in the AutoChanger and the power supplies are turned off.

-

Remove the connector by levering between the socket and the connector with a flat screwdriver. Make sure not to pull on the cable. The correct position at which the flat screwdriver has to be inserted is shown in below:

-

Remove the screw #06-LCA-13166 with a small cross-point screwdriver.

-

Pull the Sensor_XM and replace it by a new one. Make sure to fully insert the spigot of the Sensor_XM inside the clamp_XM #02-LCA-12991 as shown below:

-

Screw in the screw #06-LCA-13166 with a small cross-point screwdriver.

-

Plug the connector to the socket by pushing on the connector without bending the cables.

Sensor_YM-LCA-13160-qty2 per AutoChanger#

Scope:

This operation has to be considered if the position of the OnlineClamp Y-cannot be read on the FCS. Since every signal (OnlineClampY-Open/OnlineClampY-Closed) is doubled by a complementary one, the FCS is able to detect a sensor error.

The position of the Sensors_XP-LCA-13184 is given by #06-LCA-13036.

WARNING: the sensor corresponding to the position OnlineClampY-Closed is on the left on LCA-13036 whereas the sensor corresponding to the position OnlineClampY-Open is on the right.

Material needed:

-

Small cross-point screwdriver qty 1

-

HE_Sensor_Unpluging_Tool LCA-12981 qty 1

Procedure:

-

Make sure there is no filter in the AutoChanger and the power supplies are turned off.

-

Unscrew the screw #06-LCA-13036 with a small cross-point screwdriver.

-

Unplug the connector of the sensor with the HE_Sensor_Unpluging_Tool LCA-12981. Make sure not to pull the cable but the connector.

-

Replace the Sensor_XP-LCA-13184 by a new one.

-

Screw in the the screw #06-LCA-13036 with a small cross-point screwdriver.

LATERAL LATCH DETECTION#

Truck_Sensor_Board_XM-LCA-13006-qty1 per AutoChanger#

Scope:

This operation has to be performed if the Lateral latch detection LCA-13005 or LCA-13006 does not work properly. For instance, Filter ID reading is incorrect. Other reasons are easy to detect since every signal is doubled by a complementary one (Latch Open/LatchClosed/Filter engaged). Thus, the FCS is able to detect a sensor error.

Material needed:

-

Small cross-point screwdriver qty 1

-

External (shaft) circlip plier qty 1

Procedure:

-

Make sure there is no filter in the AutoChanger.

-

Power on the AutoChanger by turning on the tree power supplies: Clean, Safety and Dirty powers on the electrical bay.

-

Move the trucks to position 680000 using “MoveToAbsoluteTargetPosition” command on the FCS. This position corresponds to the maximal elongation of the cables between the Swing arm Plates #01-LCA-12812/#03-LCA-12812 and the Truck Plates #01-LCA-12802/#02-LCA-1282.

-

Turn off Clean, Safety and Dirty powers supplies on the electrical bay.

-

Remove the 3 screws #15-LCA-12812 that are holding the cable clamps #04-LCA-12812 with a small cross-point screwdriver.

-

Unplug the connectors of the Latch Actuator #03-LCA-12829 and those of the Lateral latch detection LCA-13005/ LCA-13006. Make sure not to pull on the cable but only on the connectors.

-

Remove the circlips #12-LCA-12802 using an external circlip plier.

-

Thoroughly remove shim rings #10-LCA-12802 and #11-LCA-12802. Make sure to identify them since you will need to put them back at the same location (thickness varies on each side of swing arm plate X minus #03-LCA-12812). Please note there is no shim rings on X plus side.

-

Unscrew the screw #15-LCA-12812 that is holding the cap #19-LCA-12812 with a small screwdriver.

-

Remove cap #19--LCA-12812 (for X plus side) or #20--LCA-12812 (for X minus side).

-

Replace the Lateral latch detection #18-LCA-12812 (for X minus side) or #17-LCA-12812 (for X plus side) by a new one.

-

Make sure there is no electrical contact between Swing arm plates #01-LCA-12812/#03-LCA-12812 and the Lateral latch detection #18-LCA-12812/17-LCA-12812. This is granted by the insulators #16-LCA-12812.

-

Put the cap #19-LCA-12812 (for X plus side) or #20-LCA-12812 (for X minus side) back.

-

Screw them by tightening #15-LCA-12812 with a small cross-point screwdriver.

-

Put back shim rings #10-LCA-12802, swing arm plate X minus #03-LCA-12812, shim rings #11-LCA-12802. (only swing arm plate X plus #01-LCA-12812 for X plus side).

-

Mount the circlips #12-LCA-12802 using a circlip plier.

-

Plug the connectors of the Latch Actuator #03-LCA-12829 and those of the Lateral latch detection LCA-13005/ LCA-13006.

-

Put the cables inside the cable clamps #04-LCA-12812 and tighten the screws #15-LCA-12812 with a small cross-point screwdriver. Make sure not to pinch the cables.

-

Power back on the autochanger by turning on Clean, Safety and Dirty power supplies on the electrical bay #04-LCA-13140.

-

Move the trucks to HandOff position using the command “GoToHandOff”.

Truck_Sensor_Board_XP-LCA-13005-qty1 per AutoChanger#

Please see section 2.1.

TRUCK POSITION SENSORS#

Truck_Position_Sensors_XM-LCA-12860-qty3 per AutoChanger#

Scope:

Replacement of Truck_Position_Sensors_XM-LCA-12860 has to be considered if the position of the truck X-cannot be read on the FCS for any of these three positions:

-

Online position (X-)

-

HandOff position (X-)

-

StandBy position (X-)

Since each of these 3 signals is doubled by a complementary one, the FCS is able to detect a sensor error.

The positions of Truck_Position_Sensors_XM-LCA-12860 are given by #03-LCA-13217. From top to bottom: HandHoff position – Online position – StandBy position.

Material needed:

-

HE_Sensor_Unpluging_Tool LCA-12981 qty 1

-

Small cross-point screwdriver qty 1

Procedure:

-

Make sure there is no filter in the AutoChanger and the power supplies are turned off.

-

Unplug the connector of the sensor with the HE_Sensor_Unpluging_Tool LCA-12981. Make sure not to pull the cable but the connector.

-

Unscrew the screw #05-LCA-12860 with a small cross-point screwdriver.

-

Replace the sensor Truck_Position_Sensors_XM-LCA-12860 by a new one.

-

Screw in the screw #05-LCA-12860 with a small cross-point screwdriver.

-

Plug back the connector on its socket. Make sure not to force on the cables but on the connector.

Truck_Position_Sensors_XP-LCA-12852-qty3 per AutoChanger#

Scope:

Replacement of Truck_Position_Sensors_XP-LCA-12852 has to be considered if the position of the truck X-cannot be read on the FCS for any of these three positions:

-

Online position (X+)

-

HandOff position (X+)

-

StandBy position (X+)

Since each of these 3 signals is doubled by a complementary one, the FCS is able to detect a sensor error.

The positions of the Truck_Position_Sensors_XP-LCA-12852 is given by #04-LCA-13217. From top to bottom: HandHoff position – Online position – StandBy position.

Material needed:

-

HE_Sensor_Unpluging_Tool LCA-12981 qty 1

-

Small cross-point screwdriver qty 1

Procedure:

-

Make sure there is no filter in the AutoChanger and the power supplies are turned off.

-

Unplug the connector of the sensor with the HE_Sensor_Unpluging_Tool LCA-12981. Make sure not to pull the cable but the connector.

-

Unscrew the screw #05-LCA-12852 with a small cross-point screwdriver.

-

Replace the sensor Truck_Position_Sensors_XP-LCA-12852 by a new one.

-

Screw in the screw #05-LCA-12852 with a small cross-point screwdriver.

-

Plug back the connector on its socket. Make sure not to force on the cables but on the connector.

LIMIT SWITCHES#

Limit_switch_position_sensor XP-LCA-13100-qty2 per AutoChanger#

This limit switch is currently not used. However, it can be replaced by the following manner:

-

Remove the screw #07-LCA-13100 with a 2mm hex. key

-

Unplug the connector with the tool: HE_Sensor_Unpluging_Tool LCA-12981

-

Replace the sensor by a new one.

-

Screw in the screw #07-LCA-13100 with a 2mm hex. key.

-

Plug back the connector to its socket by pushing on the connector. Make sur not to force on the cables.

Limit_switch_position_sensor XM-LCA-13102-qty2 per AutoChanger#

This limit switch is currently not used. However, it can be replaced by the following manner:

-

Remove the screw #07-LCA-13102 with a 2mm hex. key

-

Unplug the connector with the tool: HE_Sensor_Unpluging_Tool LCA-12981

-

Replace the sensor by a new one.

-

Screw in the screw #07-LCA-13102 with a 2mm hex. key.

-

Plug back the connector to its socket by pushing on the connector. Make sur not to force on the cables.