Slip-ring collector (un)install - inspection

| title | Slip-ring Collector Maintenance ( Carousel ) | LCA-xxxxxx | |

|---|---|---|---|

| Traveler for intervention on The Filter Exchange System & Filter Exchange system parts | Approval Status | DRAFT |

| Rev. | Revision Description | LCN# | Date |

| A.1 | Initial release, D.Laporte | 21-Apr-20 | |

| A.2 | Google Doc Update, P.antilogus | 22-Apr-20 |

| Camera Doc ID | Atrium Doc ID | Validated By | Validation Date |

|---|---|---|---|

| LCA-xxxxx | xxxxxxx |

| Initials: | Date: | ||

|---|---|---|---|

| Traveler initiated: | |||

| Traveler Closed Out: |

| Part Serial Number : | Removed: Serial ID Installed: Serial ID |

| Index Key | Value |

|---|---|

| Subsystem | Carousel |

| Operation Type | On Camera Maintenance |

| System&Action | Safety |

| Operation Name | Slip-ring collector (un)install - inspection |

| Operation Time | \~1-2h |

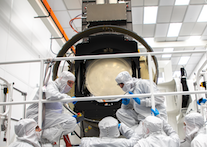

| Operation Description | The slip-ring collector does the electric connection between the electronic on the rotating pat of the carousel, and its static part: when the carousel rotates it keeps the connection to the static slip-ring “bus” , which includes power and BusCan, using the carbon brushes of the slip-ring collector. There is xxx? such slip-ring collectors distributed on the carousel ring. They are all identical and this redundancy grants a good electronic interconnection between the mobile and fixed part of the carousel. This documentation describes how to replace or access for inspection the slip-ring collector. |

| Triggered by Maintenance | The collector is a wear part. The frequency of replacement has still to be determined. It is expected that it will be at a lower frequency than the scheduled maintenance period of the camera ( \~ 2 years) . |

| Triggered by Monitoring Analysis | An increase of the number of communication errors with the mobile part of the carousel could indicate a degradation of the slip-ring collector carbon brushes. An inspection /replacement of the collector(s) could then be considered. |

| Triggered by Incident recovery | Due to the redundancy/the number of slip-ring collectors, a student interruption of communication with the mobile part of the carousel due to the slip-ring collector is unlikely, still a short due to a broken brush of one slip-ring collectors is a possibility. |

| Traveler Steps | |||

|---|---|---|---|

| 10 | WARNINGS (Personnel Safety Hazards / PPE) | ||

| 20 | CAUTIONS (Equipment Damage Hazards) | ||

| 20,10 | Do no pull on cables to prevent even small tension loads from overloading single wires and breaking them | ||

| 20,20 | Be careful to not drop/spread grease, ex: Brake teethes will have grease | ||

| 30 | Applicable Documents and Drawings | Ref./link | Type |

| 30,10 | Mobile Carousel Assembly | LCA-12500 | Drawing |

| 30,20 | Assembly Gear | OSNLT229 | Drawing |

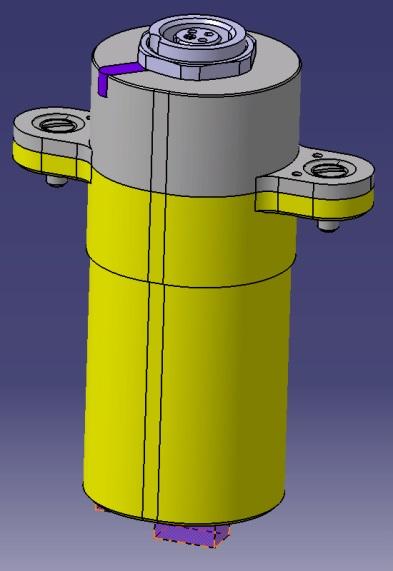

| 30,30 | Slip-ring_power_collector | LCA-12680_OSNLT943 | Drawing |

| 30,40 | Slip-ring_CANbus_collector | LCA-12670_OSNLT927 | |

| 40 | Tools Required | Ref. | Quantity |

| 40,10 | Tournevis plat n° ??? | 1 | |

| 50 | Parts, Materials, and Consumables | Ref. | Quantity |

| 50,10 |  | LCA-12670 | 5 |

| 50,20 |  | LCA-12680 | 5 |

| 60 | Useful Comments & Remarks | ||

| 60,10 | |||

| 60,20 |

| 100 | Disconnect the connector : unscrew it | Initials | Date |

|---|---|---|---|

| 100,10 | Unscrew the connector | ||

| 100,20 | Unscrew the captive screwswith the tournevis plat | ||

| 100,30 | Remove the collector | ||

| 200 | Cleanning | Initials | Date |

| 200,10 | |||

| 300 | Initials | Date | |

| 300,10 | |||

| 400 | Initials | Date | |

|---|---|---|---|

| 400,10 | |||

| 500 | Initials | Date | |

| 500,10 |

| 600 | Initials | Date | |

|---|---|---|---|

| 600,10 | |||

| 700 | Initials | Date | |

| 700,10 | |||

| 800 | Initials | Date | |

| 900 | Initials | Date | |

|---|---|---|---|

| 900,10 | |||

| 1000 | Initials | Date | |

| 1000,10 | |||

| 1100 | Initials | Date | |

| 1100,10 | |||

| 1200 | Initials | Date | |

| 1200,10 | |||

| 1300 | Initials | Date | |

| 1300,10 |

| 1400 | Screw back the brake : M6X30 (x4) | Initials | Date |

|---|---|---|---|

| 1400,10 | |||

| 1500 | Reconnect brake sensor | Initials | Date |

| 1500,10 | |||

| 1600 | Remount backflange parts x2 , with 2 screws each | Initials | Date |

| 1600,10 |

| 9999 | End Of Traveler | Initials | Date |

|---|---|---|---|

| 9999,10 | Work complete |